Code Compliance

IFS has over the years been asked by thousands of people in all 50 states for an easily accessible and easy to use guide that helps explain their Code Compliance issues concerning FR Decorations, Interior Finishes, and Thermal Barrier Applications.

With the combined efforts of many in-house and outside resources, this resource is intended for use by personnel and administrators of areas of public assembly and occupancy classifications to maintain and improve life safety conditions for the benefit of residents and employees. This document is intended to provide information to facilities, but it is not necessarily fully inclusive of all details of LSC 2000 or other NFPA Standards. Determinations of compliance with Life Safety Code regulations are made at the time of survey.

Federal, State and Municipal Building Codes all have maintenance clauses pertaining to the flame retardancy of decorative materials and interior finishes when used in areas of assembly or egress. Many have established on-going maintenance cycles, protocol and recertification programs for fire-retardant materials whose cycles vary in length of time. Any flame retardant or resistant item that has had its fire resistant coating removed or has had a flammable coating (including, but not limited to airborne dust and flammable paints) applied or adhered to its surface, will have negated its flammability rating and must be, at that point, MAINTAINED to certify its original flame retardant condition.

New construction and retrofits of existing facilities are also required to meet the current codes established. Certificates of Flameproofing Conformance are provided for items that meet applicable Code Standards. When Certificates of Flameproofing Conformance expire, the liabilities of the flame retardancy of those treated items are no longer the responsibility of the company originally issuing the certificate.

ICC Chapter 8 Interior Finishes, Decorative Materials and Furnishings - Full text

NFPA 703 and Life Safety Code 101 for Interior Finishes clearly states that "Interior Finishes in areas of Public Assembly shall meet the required Fire Codes for that Occupancy and that the Fire Retardant properties on treated items be Maintained or Renewed as per Manufacturer's Instructions and under the service conditions of actual use, using only approved flame retardant coatings."

In 2010 the Center for Medicaid (CMS) issued a Corrective Memorandum entitled "Interior Finish Documentation Requirements for Multiple Providers."

- Clarifies Policy on Interior Finish -- this memorandum clarifies policy regarding existing interior finish for fire safety purposes.

- No Requirement to Document Flame Spread Rating -- existing interior finish materials.

- Documentation of Flame Spread Rating Required -- only for newly installed interior finish materials.

The memo states that… “Generally these finishes are renewed on a regular basis when the facility updates and refreshes its interior and can obtain the needed documentation at that time.” You can read the full text here.

IFS - 1500° Series Paints & Varnishes

806.2.6 Fire-retardant coatings. The required flame spread or smoke-developed classification of surfaces shall be permitted to be achieved by application of approved fire-retardant coatings, paints or solutions to surfaces having a flame spread rating exceeding that permitted. Such applications shall comply with NFPA 703 and the required fire-retardant properties shall be maintained or renewed in accordance with the manufacturer's instructions.

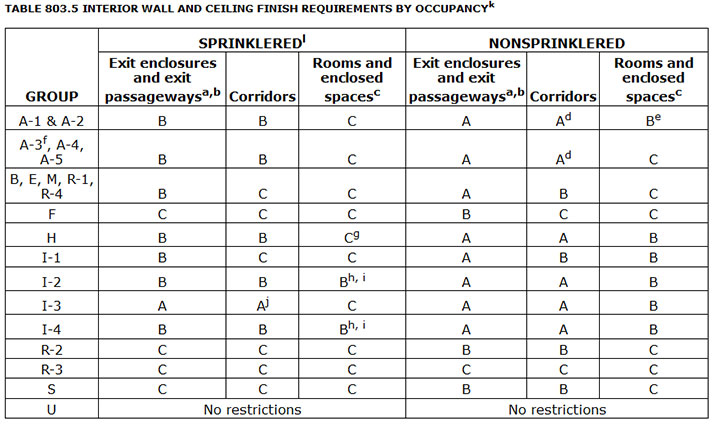

806.3 Wall and ceiling finish requirements. Interior wall and ceiling finish shall have a flame spread index not greater than that specified in Table 806.3 for the group and location designated. Interior wall and ceiling finish materials, other than textiles, tested in accordance with NFPA 286 and meeting the acceptable criteria of Section 806.2.1.1, shall be permitted to be used where a Class A classification in accordance with ASTM E84 is required.

GROUP DESCRIPTIONS

| Group | Description | Group | Description | Group | Description | Group | Description |

|---|---|---|---|---|---|---|---|

| A-1 | Theaters | B | Business | F | Factory/Industrial | I-4 | day-care facilities for 6 or more persons not capable of self-preservation |

| A-2 | Dining & drinking (food/drink) | E | Educational (through 12th grade) | H | Hazardous Occupancies | R-2 | Apartments, Dormitories, Fraternities, Sororities |

| A-3 | Auditoriums, gymnasiums, museums | M | Mercantile | I-1 | Institutional (>16 persons) | R-3 | 1 & 2 family homes, supervised living facilities |

| A-4 | Arenas, swimming pools, tennis courts | R-1 | Hotels/Motels, B & B's | I-2 | Hospitals, nursing homes, supervised living facilities | S | Storage |

| A-5 | Stadiums, grandstands | R-4 | Residential care & assisted living for 6-16 people | I-3 | Jails, prisons | U | Miscellaneous |

For SI: 1 inch = 25.4 mm, 1 square foot = 0.0929 m2.

a. Class C interior finish materials shall be permitted for

wainscotting or paneling of not more than 1,000 square feet of

applied surface area in the grade lobby where applied directly

to a noncombustible base or over furring strips applied to a

noncombustible base and fireblocked as required by Section

803.4.1.

b. In vertical exits of buildings less than three stories in

height of other than Group I-3, Class B interior finish for

nonsprinklered buildings and Class C interior finish for

sprinklered buildings shall be permitted.

c. Requirements for rooms and enclosed spaces shall be based

upon spaces enclosed by partitions. Where a fire-resistance

rating is required for structural elements, the enclosing

partitions shall extend from the floor to the ceiling.

Partitions that do not comply with this shall be considered

enclosing spaces and the rooms or spaces on both sides shall be

considered one. In determining the applicable requirements for

rooms and enclosed spaces, the specific occupancy thereof shall

be the governing factor regardless of the group classification

of the building or structure.

d. Lobby areas in Group A-1, A-2 and A-3 occupancies shall not

be less than Class B materials.

e. Class C interior finish materials shall be permitted in

places of assembly with an occupant load of 300 persons or

less.

f. For churches and places of worship, wood used for ornamental

purposes, trusses, paneling or chancel furnishing shall be

permitted.

g. Class B material is required where the building exceeds two

stories.

h. Class C interior finish materials shall be permitted in

administrative spaces.

i. Class C interior finish materials shall be permitted in

rooms with a capacity of four persons or less.

j. Class B materials shall be permitted as wainscotting

extending not more than 48 inches above the finished floor in

exit access corridors.

k. Finish materials as provided for in other sections of this

code.

l. Applies when the vertical exits, exit passageways, exit

access corridors or exitways, or rooms and spaces are protected

by a sprinkler system installed in accordance with Section

903.3.1.1 or 903.3.1.2.

Decorative Materials IFC Chapter

8, NFPA Life Safety Code Chapter 8 -

Full text

Curtains, draperies, hangings and other decorative materials

suspended from walls or ceilings shall be certified meet the

flame spread criteria of NFPA 701 or shall be

non-combustible.

Inherently Flame-Retardant

(IFR) Materials – NFPA 701-2010 and current Fire Code

Compliance

Inherently Fire Retarded Fabrics

Buyers and Fire Inspectors should be aware of two (2)

categories of Inherently Flame Retardant textiles. Those whose

flammability performance is based upon Additives (FRT) at the

processing stages and those textiles which are Inherently Fire

Resistant such as Kevlar, Nomex and Asbestos. Both are often

marketed as Inherently Flame Retardant (IFR).

Unless Inherently Flame Retardant Fabrics are Truly Kevlar,

Nomex or Asbestos in origin, fabrics labeled Inherently Flame

Retardant could lose their Fire Resistance due to aging,

humidity, laundering or airborne dust. Many older (FRT) IFR’s

will not pass simple flammability field tests that are

indicative of Flame Resistance.

Dupont

Ref: www.dupont.com (regarding Inherently Flame Resistant

Fabrics)

“These materials are made flame-resistant by the application of

flame-retardant chemicals. A chemical additive in the fiber or

treatment on the fabric is used to provide some level of flame

retardancy”,

“FR-treated garments may be damaged by chlorine bleach with

hard water, or exposure to oxidizing chemicals in the

workplace”, “exposure to oxidizing could, over time, compromise

the flame-resistant properties of garments made with FR-treated

fabrics.”

I Weisse

Ref: www.iweiss.com (regarding Inherently Flame Resistant

Fabric)

“IFR Fabrics are manufactured from polyester yarns to meet NFPA

701 testing protocol without any additional treatment. These

fabrics are expected to retain their IFR properties for the

life of the material, however, THIS CANNOT BE GUARANTEED.

Conditions of use including time, humidity, excessive dust or

dirt etc. may adversely affect the flame retardant

capabilities. A yearly field test to verify the status is

strongly recommended.”

“These fabrics are expected to retain their IFR properties for

the life of the material. However, it should be understood that

IFR does not mean permanently flame proofed. Ambient

conditions, cleaning practices, excessive dust build up, etc.,

can affect the fabric's flammability characteristics. This is

true of synthetic IFR fabric or any other cellulose constructed

and chemically treated fabric. Proper care, cleaning, and

periodic testing can maintain the proper characteristics.”

Dazian

Ref: www.dazian.com regarding Inherently Flame Resistant

Fabrics)

“A Flame Retardant additive is added to the fiber to give the

fabric Permanent Flame Resistance. A topical finish is often

added in fabric dyeing and finishing insuring in fabric

formation the FR properties are maintained. Although there may

be no degradation from washing or dry cleaning, the same

factors of environment, use of added components and further

processing may compromise its flame resistance. Retesting every

few years and re-flameproofing may still be required.”

International Fire-Shield, Inc.’s

Inspecta-Shield Plus fire

retardant.

Furnishings IFC Chapter 8, NFPA

Life Safety Code Chapter 8 -

Full text

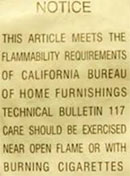

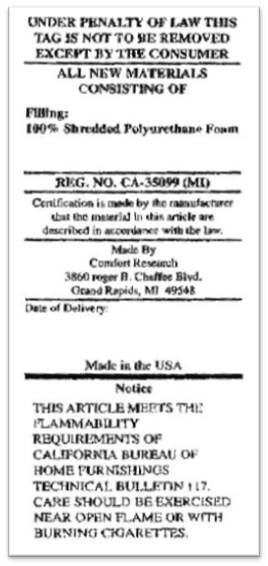

Upholstered furniture and mattresses must meet the flammability

criteria as established by ASTM E 1537 or

California Technical Bulletin 133 (Mattresses are

required to meet California Technical Bulletin 129)

The Cal Tech 133 is the prescribed

test method for furniture flammability requirement in areas of

public occupancy.

California Technical Bulletin

117 is a mandatory standard for residential upholstered furniture. The

furniture fabric covering is not tested

for flammability. However, there are thousands of public

occupancies that contain upholstered furnishings that only meet

the Cal Tech 117 test requirements.

To correct this oversight Inspecta-Shield Plus can be

used to flame retard the fabric.

IN I-1, I-2 and R-4 OCCUPANCIES

The ICC Building Code Chapter 5 General Building Heights and Areas is the driver of assembly ratings for areas of incidental use and accessory areas in conjunction with Chapter 3. From Chapter 5 requirements can be linked to for the specified type of occupancy.

As an example, if an R-4 has a change in the ambulatory occupancy and becomes classified as an I-2 the fire codes can change dramatically overnight (ICC Interpretation No. 16-03). If there is an accessible basement that is used for storage this area becomes classified as an Incidental Use area or an accessory area depending on the square feet of the area and is now a separate fire area of the structure.

This area for storage is now classified as an S-1 (Moderate Hazard) or S-2 (Low Hazard) depending on the materials stored (Chapter 3 Section 311). The entire structure is now a mixed use non-separated occupancy. Chapter 5 Section 508.3.1 assists in determining if this is an Incidental or Accessory area. Chapter 3 breaks down the classification process of an S-1 and S-2.

Chapter 5 section 508 Tables 508.2 and 508.3.3 can be used to determine the floor, floor/ceiling assembly hourly requirements required for this type of mixed use occupancy. The use of these tables will help to determine if a sprinkler system or hourly rated assembly is required or if both are required.

There are additional sections of the Code that deal with the type of construction, size of the area below grade, number of exits to the exterior of the structure and distances to these exits that are referenced from Chapter 5 that are also used to complete the determination of the type of assembly needed. Chapter 5 is a good index starting point to determine your needs for Code Compliance in all occupancies.

ICC Chapter 6 Types of Construction

Combustible Material in Type I and II Construction IBC Chapter 8 - Full text

Fire retardant treated wood may be used in various wall assemblies, attics and roof construction, including girders, trusses, framing and decking.

In October of 2010 the NFPA Technical Committee on Board and Care Facilities met to revise Section 26.2.6 Attic Protection, 26.2.3.5.6, and 26.2.3.5.7. Attics shall meet one of the following criteria: 1) Heat detection; 2) Sprinklers; 3) Non combustible construction; 4) Be treated with a Fire Retardant to meet NFPA 703.

Even with Sprinkler systems the residents needed additional time to evacuate the building due to type of occupancy. When attics are used for living purposes, storage or fuel fired equipment it shall be constructed of fire retardant treated wood in accordance with NFPA 703 Standard for Fire Retardant Treated Wood and Fire Retardant Coatings for Building Materials.

Accessible exposed Framing and Plywood located in attics treated with Inspecta-Shield Plus qualifies as a Class “A” finish in accordance with IBC Section 803.1.1, and Chapter 5 of NFPA 703 as listed in ICC Evaluation Report NO ESR-2019.

IBC Chapter 8 Fire and Smoke Protection Features

Interior Wall, Floor, Floor/Ceiling Assemblies and Smoke and Fire Doors shall meet the hourly thermal barrier rating for the occupancy they are installed in.

IBC Chapter 26 Foam Plastic Insulation

Exposed sprayed polyurethane foam and foam board shall meet ASTM E-84 Class “A” flame spread and shall be protected by either an Ignition Barrier or Thermal Barrier depending on the location of the installation. Full text

International Fire-Shield, Inc.’s 1500° Series Foam Barrier

International Fire Code & Uniform Building Code - Chapter 8 Interior Finishes and Decorative Materials

SECTION 302 USE & OCCUPANCY CLASSIFICATION

302.1 General. Structures or portions of structures shall be classified with respect to occupancy in one or more of the groups listed below. A room or space that is intended to be occupied at different times for different purposes shall comply with all of the requirements that are applicable to each of the purposes for which the room or space will be occupied. Structures with multiple occupancies or uses shall comply with Section 508. Where a structure is proposed for a purpose that is not specifically provided for in this code, such structure shall be classified in the group that the occupancy most nearly resembles, according to the fire safety and relative hazard involved.

1. Assembly (see Section 303): Groups A-1, A-2, A-3, A-4 and A-5

2. Business (see Section 304): Group B

3. Educational (see Section 305): Group E

4. Factory and Industrial (see Section 306): Groups F-1 and F-2

5. High Hazard (see Section 307): Groups H-1, H-2, H-3, H-4 and H-5

6. Institutional (see Section 308): Groups I-1, I-2, I-3 and I-4

7. Mercantile (see Section 309): Group M

8. Residential (see Section 310): Groups R-1, R-2, R-3 and R-4

9. Storage (see Section 311): Groups S-1 and S-2

10. Utility and Miscellaneous (see Section 312): Group U

Code Compliance History - the NFPA and the formation of the ICC

Since the early 1900s, US Fire Code Regulations were regionalized within the US through ICBO, BOCA and SBCCI. In 1994 these regional sections merged to form the International Code Council (ICC) to create a coordinated uniformity in national building codes.

In 1997 the first edition of the International Building Code (IBC) was published by the ICC. Most States have adopted the ICC Codes or parts thereof that address Fire Code, Residential Code, Existing Building Code, and other areas. Many states and municipalities also use the NFPA 101 Life Safety Code for Fire Code Requirements. These codes establish minimum requirements based on occupancy classification.

The National Fire Protection Association (NFPA) originally worked in conjunction with ICC to establish standard requirements for the IBC and other ICC Codes including the International Fire Code. Repeated failures and disputes between the two organizations over the minimum requirements to be adopted led the NFPA to withdraw from any further collective efforts of writing the IFC or other codes published by the ICC.

The IFC and NFPA 101 Life Safety Code can often times be difficult to combine as occupancy classifications and requirements can differ between the two organizations and can lead to interpretation conflicts when combining the two together.

International Fire-Shield, Inc. works with Code Compliance Officials to make sure that our products are accepted for use to meet your specific local Code requirements.